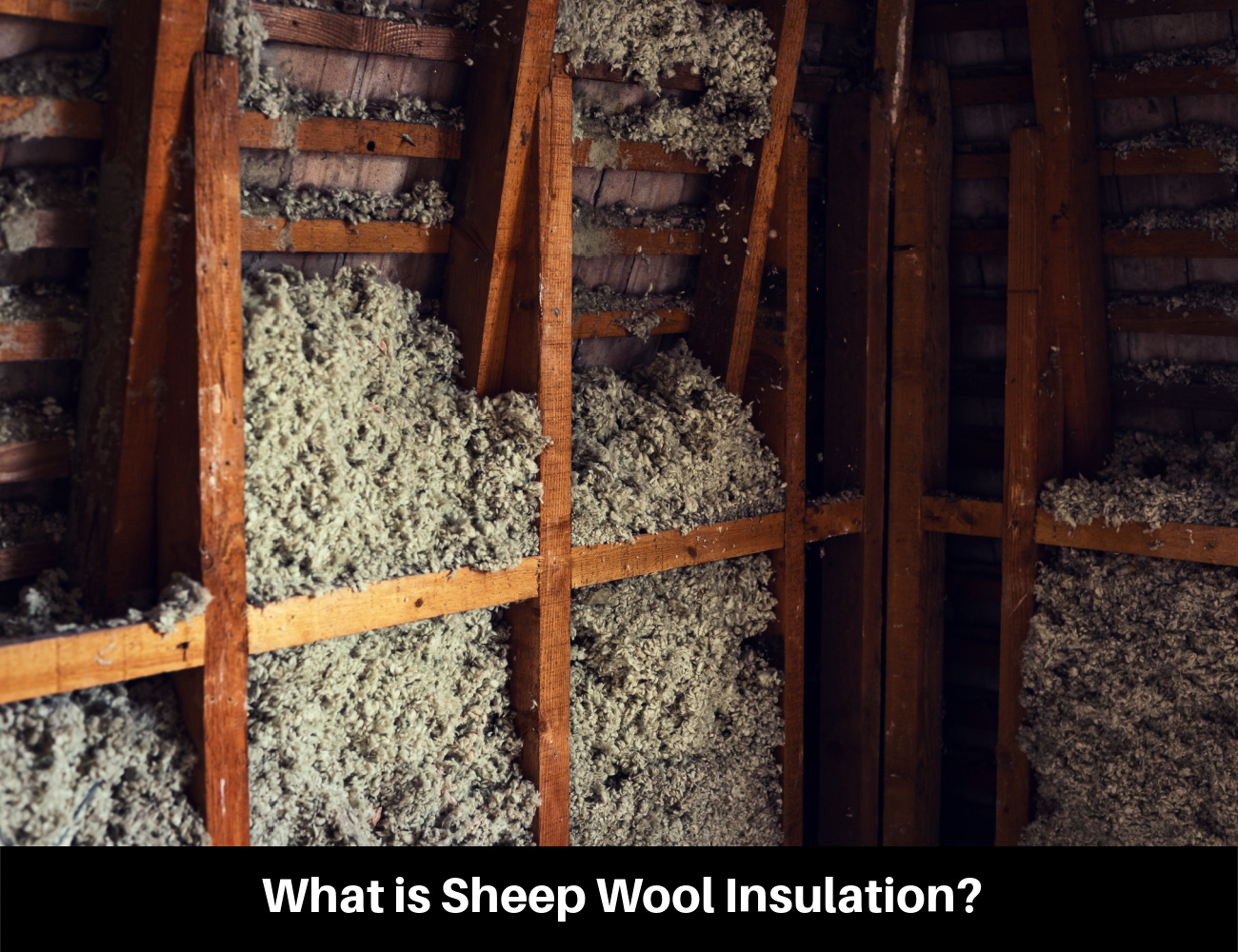

Sheep wool insulation is manufactured from the fleece of sheep, and it’s often called wool insulation. Not to be confused with mineral wool insulation manufactured from rock. Or hemp wool insulation manufactured from hemp plants. Sheep wool is one of the more eco-friendly insulations available: Renewable, Biodegradable, Formaldehyde-free.

How Sheep Wool Insulation Is Made

Sheep wool insulation is manufactured from wool that is less desirable to the fabric industry–such as black wool and wool from the legs and underbellies of the animal. Some companies use 5% – 20% polyester as a bonding agent in batts.

Some use no bonding agents; preferring to entangle the wool into knops or balls that hold air. Dead air spaces provide the thermal resistance in most types of insulation.

Sheep wool insulation is popular in Europe, Canada, and Australia which produces 55% of the world’s raw and processed wool. It is becoming more common in the US where over five million sheep are grown–providing abundant raw material.

Pros:

Sheep wool is a viable alternative to many traditional types of insulation.

- R-value. R-3.6 – R-4.3. Similar to fiberglass insulation and cellulose insulation.

- Hygroscopic. Excellent insulation for high-humidity locations. Can absorb up to 33% of its weight in moisture without losing insulation value. Then release it back into the house to moderate temperatures and comfort.

- Fireproof. Naturally fire resistant. Does not support flame at temperatures below 1040 degrees F. Considered a self-extinguishing material because of its high nitrogen content.

- Sound Absorbing. Excellent sound absorption. Noise reduction coefficient (NRC) of 0.95 – 1.15. Can be used as soundproofing for home theaters and band rooms.

- Mold Resistant. Does not provide a medium for mold growth even when wet.

- Environmentally Friendly. Renewable resource. Uses 15% of the amount of energy used to produce fiberglass insulation.

- Non-sagging. Elasticity of wool prevents sagging inside stud cavities.

- Durable. Resists breaking, tearing, and abrasion.

- Breathable. Air moves freely through wool without reducing its insulation value.

Cons:

Sheep wool is not the perfect insulation product. Here are a few things to take into consideration.

- Cost – R-13 wool batts cost about $2.40 per square foot. More than twice the cost of fiberglass and more than mineral wool. Sheep wool combined with more polyester costs less.

- Chemicals – Sheep wool insulation is treated with pest control chemicals during the manufacturing process. Most of them are fairly benign but sensitive people may experience some discomfort–especially during installation and before the insulation is covered.

- Odor – Wool is washed during the manufacturing process to remove dirt, insects, and pesticides. Farmers may treat their animals with pesticides and fungicides to reduce pest infestations. Natural waxes in wool also have an odor. Wool is usually washed three times during production but it still may have a slight odor that sensitive people can detect.

- Pests – Untreated or poorly treated wool attracts moths and other pests. Moth infestations can reduce insulation value. Severe infestations may require the complete removal and replacement of the insulation.

Keeping the Moths Out

Wool is very susceptible to pest infestations–especially moths. Four of the most common pest control agents added to wool are:

- Borax. Acts as a pest repellant and additional fire retardant. (Wool is naturally fire resistant.) Can be dusty during installation. Used in many other products such as cellulose insulation. Generally considered safe but increasingly suspected of having reproductive and developmental effects. Classified as a reproductive toxin in Europe.

- Diatomaceous Earth (DT). Safe effective organic pesticide. Only works in loose-fill wool. Dusty during installation.

- Thoralin IW. Titanium-based moth repellent. It is applied hot to the face of batts. Remains effective for the lifetime of the wool. On the European Union’s list of certified products.

- Eulan SPA. Non-toxic. Derived from chrysanthemums.

Types of Sheep Wool Insulation

Sheep wool insulation is made into batts, rolls, knops (defined as an ornamental tuft of yarn), and ropes. Batts and rolls are produced in a variety of thicknesses and standard stud cavity widths of 16” and 24”. Knops are small wool bits used as loose fill to blow into attics or walls. Mesh is used to hold the product in wall cavities until drywall can be applied. Wool ropes are used as chinking between the log courses of log homes.

Sheep wool batts are not available as a faced product that acts as a vapor barrier and is stapled to the studs. A vapor barrier of 6 mil poly should be installed on the warm side of the wall. It may also be necessary to staple the edges of wool batts to the studs to prevent slumping before drywall is installed.

R-value Of Sheep Wool Insulation

Sheep wool batts and rolls have an R-value of R-3.6 per inch. Putting it in the same range as fiberglass insulation, mineral wool insulation, and cellulose insulation. Loose fill is R-4.3–significantly higher than cellulose and mineral wool blown-in insulation.