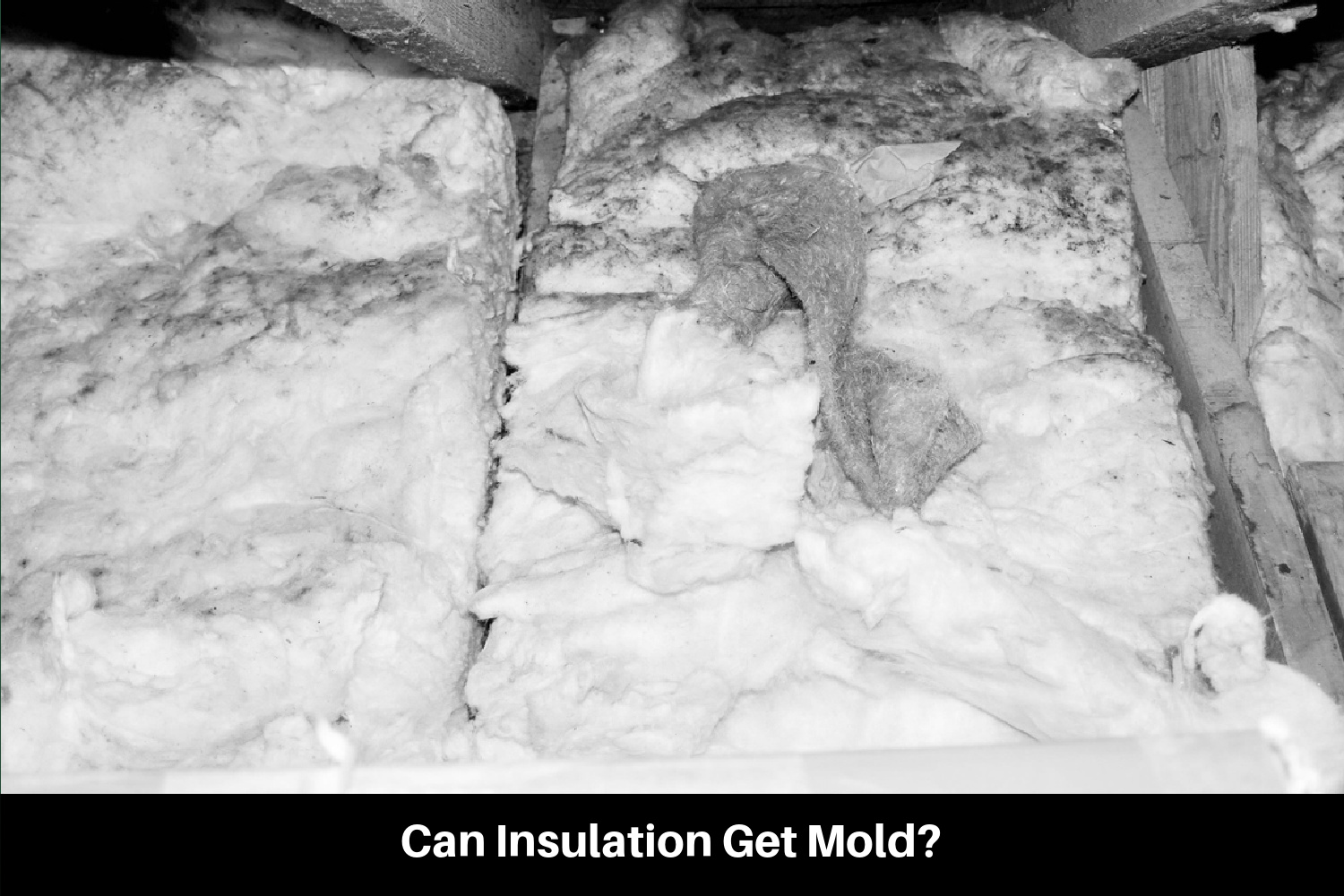

Most types of insulation products do not support mold growth. But they attract and hold the organic dust and moisture that mold will grow on. Meaning that the insulation shares the blame. Clean dry insulation is usually mold-free.

What Causes Mold?

Mold spores are present in the air. They enter every house through open windows and doors, gaps and cracks in the building envelope, and any other opening. Once inside, the spores need three conditions to form a colony.

- Humidity. Relative humidity consistently above 50%.

- Temperature. Between 40 degrees F and 120 degrees F.

- Food. Almost any organic material including dust.

Mold Growth on 8 Common Insulation Types

Insulation can get wet. Most wall and ceiling insulation is covered by drywall. Attic insulation is very seldom inspected. The first indication of a problem is the musty moldy smell. Followed by black spots on walls or ceilings. These are indications of wet insulation.

1. Fiberglass

Mold can grow on and in fiberglass insulation–both batts and loosefill. It does not feed on the insulation but on the organic dust trapped by the air pockets in the product. Once moisture is added, the spores will begin feeding and expanding. The mold will also spread to surrounding framing and drywall.

When it gets wet, the paper used to manufacture faced fiberglass insulation provides a ready food source for mold. The paper acts as a vapor barrier to keep the insulation dry, but condensation can gather on the warm facing.

2. Cellulose

Cellulose insulation–loose fill and batts–is 85% recycled paper. A perfect food for mold. It is treated with boric acid to help resist fire, pests, and mold. Mold will not grow on cellulose even when wet.

Cellulose traps and holds moisture and clumps and sags against the surrounding wood. When wet cellulose contacts wood framing members–like studs, rafters, joists, or plywood–mold growth can occur because wood is not treated to resist mold. Wet cellulose will soak drywall and enable it to support mold growth.

3. Mineral Wool

Mineral wool insulation is manufactured using inorganic lava rock and iron slag. The material itself does not absorb moisture or support mold growth. However, dust adheres to the batts and gets into air pockets. The dust absorbs moisture and provides a home for mold spores to grow.

4. Denim

Denim insulation–also known as cotton insulation–absorbs moisture like a sponge. It makes all of the wood framing around it wet. Moist warm wood grows mold easily. Without a vapor barrier, the moisture will penetrate drywall and mold will appear inside the home.

Wet denim is almost impossible to dry out and reuse. It has to be removed and replaced after the leak or source of condensation is fixed.

5. Cork

Cork insulation is naturally mold-resistant. It contains no additives. Also, very few exposed air pockets to hold dust. It sheds water and does not absorb moisture. Mold almost never grows on or near cork.

6. Sheep Wool

Sheep wool insulation has naturally mold-repellent properties. (Wet wool clothing never gets moldy.) Wool absorbs moisture in humid conditions and releases it when the air dries out–providing natural humidity control. Sheep wool can absorb up to 35% of its weight in moisture and still does not support mold growth.

7. Spray Foam

Closed cell spray foam insulation is moisture resistant when cured. It does not absorb water. Mold does not grow in it or on it. Spray foam reduces water and air penetration- and condensation by sealing all gaps and cracks in the building envelope. Plumbing leaks in wall cavities can still cause mold growth–but on the wood and drywall. Not on the foam insulation.

8. Rigid Foam Boards

Rigid foam board insulation contains up to 98% air but the closed-cell construction resists moisture absorption. Dust can adhere to the surface and may provide a food source for mold spores. Mold does not feed on the foam itself.

Rigid foam boards installed between studs or on basement walls must be sealed with spray foam in a can or acoustic caulking to prevent cold air and moisture penetration. Any moisture can condense on the insulation and surrounding wood–giving mold colonies a source of food.

Adverse Health Effects of Mold

A 1999 Mayo Clinic study states most of the 37 million cases of chronic sinus infections in the US are caused by mold spores. Off-gassing of Volatile Organic Compounds (VOC) can also increase as mold rots and degrades the material it is growing on. Mold can set off severe asthma attacks in sensitive people.

Controlling Mold Growth On Insulation

Mold spores will get into the house. They are reasonably benign until they start growing. Removing any one of the growth conditions prevents colonies from growing. Common home temperatures are well within mold spores’ comfort range. Organic material is everywhere. Dust, wood framing, drywall (paper wrapping), carpets, etc. Moisture and humidity set the growth process in motion. Here are a few suggestions to prevent mold on insulation.

- Keep home humidity consistently below 50%. Use a dehumidifier if necessary.

- Provide air movement throughout the house.

- Insulate with rigid foam, spray foam, cork, or sheep wool.

- Use mold-resistant paint.

- Insulate plumbing pipes and ducting to prevent condensation.

- Encapsulate crawl spaces. Or ensure insulated crawl spaces are well ventilated.

- Remove wet insulation and mold immediately. Use bleach or commercial mold-killer to eliminate all infestations.

- Dry or dispose of wet carpets.